Nickel Alloy 20 (UNS N08020) /DIN2.4660

| Alloy | ihe | C | Si | Mn | S | P | Ni | Cr | Nb+Ti | Fe | Cu | Mo |

| Alloy 20 | Nkeji |

|

|

|

|

| 32.0 | 19.0 | 8*C |

| 3.0 | 2.0 |

| Max | 0.07 | 1.0 | 2.0 | 0.035 | 0.045 | 38.0 | 21.0 | 1.0 | nguzozi | 4.0 | 3.0 |

| Ọnọdụ Aolly | Ike ọdụdọ Rm Mpa Nkeji. | Ike mmeputa RP 0.2 Mpa Nkeji | Ogologo A5 nkeji % |

| A gbajiri agbaji | 620 | 300 | 40 |

| Njupụtag/cm3 |

| 8.08 |

Mkpanaka, Ogwe, Waya na Ngwa Ngwakọta- ASTM B 462 ASTM B 472, ASTM B 473, ASME SB 472, ASME SB 473,

Efere, mpempe akwụkwọ na mpempe akwụkwọ- ASTM A 240, ASTM A 480, ASTM B 463, ASTM B 906, ASME SA 240,

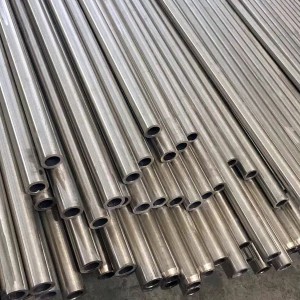

Paịpụ na Tube- ASTM B 729, ASTM B 829, ASTM B 468, ASTM B 751, ASTM B 464, ASTM B 775, ASTM B 474,

Ndị ọzọ- ASTM B 366, ASTM B 462, ASTM B 471, ASTM B 475, ASME SB 366, ASME SB-462, ASME SB

Ezigbo n'ozuzu iguzogide nchara na sulfuric acid

Nguzogide dị mma megide mgbawa nchara chloride

Ezigbo ihe eji arụ ọrụ na ihe eji emepụta ihe

Mmiri kacha nta nke carbide n'oge ịgbado ọkụ

Ọ na-eme nke ọma n'iguzogide mmebi na asịd sulfuric dị ọkụ