Nickel 200/Nickel 201/ UNS N02200

| Alloy | ihe | Si | Mn | S | Ni | Fe | Cu |

| Nickel 200 | Nkeji | ||||||

| Max | 0.35 | 0.35 | 0.01 | 99.0 | 0.4 | 0.25 | |

| Ihe ngosi | Ihe mejupụtara nickel 201 C bụ 0.02, ihe ndị ọzọ dị na nickel 200 bụ otu ihe ahụ. | ||||||

| Ọnọdụ Aolly | Ike ọdụdọ Rm Min Mpa | Ike mmeputa RP 0. 2 nkeji Mpa | Ogologo Nkeji 5% |

| a kụrisịrị | 380 | 105 | 40 |

| Njupụtag/cm3 | Ebe Mgbaze℃ |

| 8.89 | 1435~1446 |

Mkpanaka, Ogwe, Waya na Ngwa Ngwakọta- ASTM B 160/ ASME SB 160

Efere, mpempe akwụkwọ na mpempe akwụkwọ -ASTM B 162/ ASME SB 162,

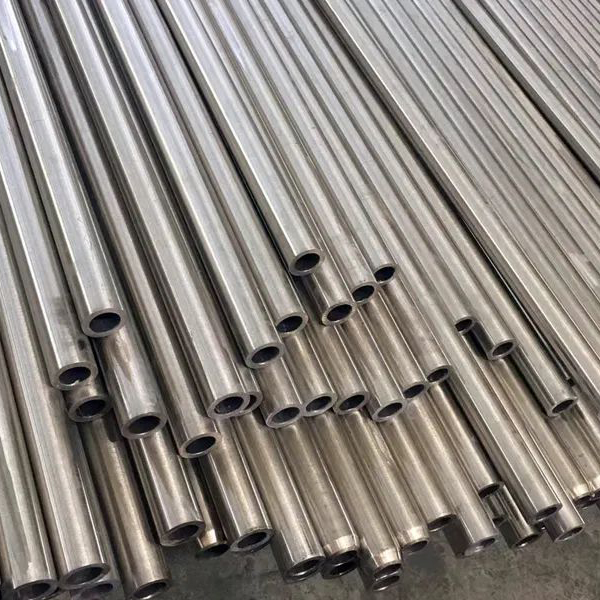

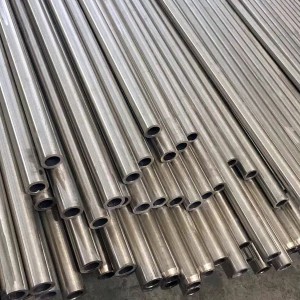

Paịpụ na Tube- ASTM B 161/ ASME SB161, B 163/ SB 163, B 725/ SB 725, B730/ SB 730, B 751/ SB 751, B775/SB 775, B 829/ SB 829

Ngwa ndị dị mkpa- ASTM B 366/ ASME SB 366

● Na-eguzogide ọgwụ dị iche iche na-ebelata oke

● Nguzogide dị mma megide alkali caustic

● Ike eletrik dị elu

● Ezigbo iguzogide nchara na mmiri e siri esi na nke eke

● Mgbochi nke ngwọta nnu na-anọpụ iche na nke alkaline

● Ọ dị mma iguzogide fluorine akọrọ

● A na-ejikarị ya eme ihe n'ọtụtụ ebe maka ịsa soda caustic

● Ezigbo ihe onwunwe okpomọkụ, eletriki na magnetostrictive

● Na-enye obere iguzogide hydrochloric na sulfuric acid na obere okpomọkụ na njupụta