Invar alloy 36 /UNS K93600 na K93601

| Alloy | ihe | C | Si | Mn | S | P | Ni | Fe |

| Invar 36 | Nkeji |

|

| 0.2 |

|

| 35.0 |

|

| Max | 0.05 | 0.2 | 0.6 | 0.02 | 0.02 | 37.0 | nguzozi |

| Ọnọdụ Aolly | Nkezi Ngụkọta Ahịrị (10)-6/°C) | ||||

| 20~50℃ | 20~100℃ | 20~200℃ | 20~300℃ | 20~400℃ | |

| a kụrisịrị | 0.6 | 0.8 | 2.0 | 5.1 | 8.0 |

| Njupụtag/cm3 | Ebe Mgbaze℃ |

| 8.1 | 1430 |

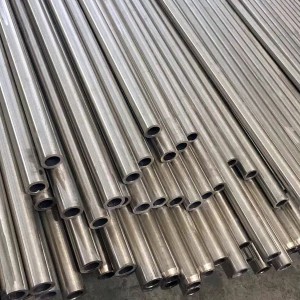

Mkpanaka, Ogwe, Waya na Ngwa Ngwakọta

Efere, mpempe akwụkwọ na mpempe akwụkwọ -ASTM B 388 na B 753

Dee ozi gị ebe a zitere anyị ya